BIONOMIC INDUSTRIES

Chemical Recovery / Production Systems

Capture and Reuse Gas Stream Pollutants with Modular Recovery Systems

There are dozens of applications and products that meet the gas composition and other criteria needed to enable an economic recovery solution. Recovery of scrubbed products and by-products can be the best most cost effective viable option to meet emission standards. It also allows recycling and reuse of the scrubbed product to save the cost of liquid waste stream treatment.

Bionomic Industries has the process and systems engineering know how to offer an effective and complete solution to meet your exact application requirements.

Hundreds of Bionomic recovery systems are hard at work on applications in the chemical, fertilizer, metals, pulp and paper, petroleum, energy, electronics and general manufacturing industries.

Examples of Bionomic custom designed recovery/production systems in ongoing operation resulting in continuous cost savings includes:

Re-concentration of acids: acetic, hydrochloric, hydrobromic, hydrofluoric, nitric and chromic

Recovery of ammonia to ammonium hydroxide

Conversion of ammonia into valuable ammonium sulfate, nitrate or phosphate fertilizer products

Nitrogen oxide conversion to nitric acid

Recovery of Dimethyl Formamide (DMF)

Caustic bath recovery

Manufacture of PCC (precipitated calcium carbonate) using carbon dioxide rich flue gas

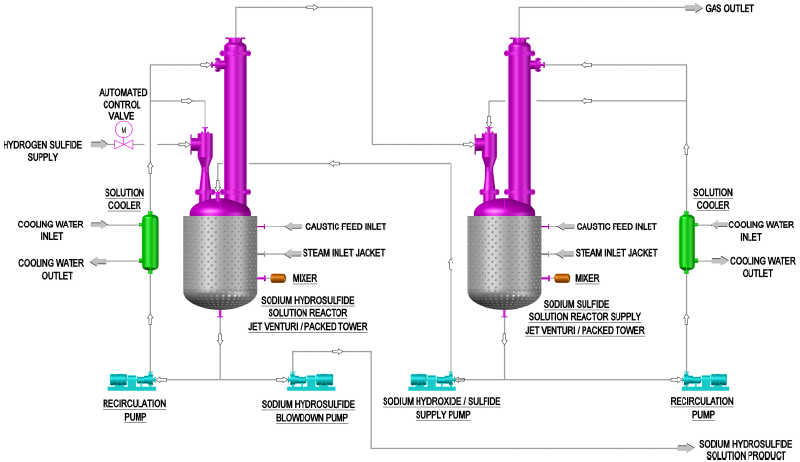

Conversion of hydrogen sulfide to sodium hydrosulfide (NaHS) - Click here to learn about our NaHS Production Systems

Conversion of sulfur dioxide to sulfuric acid or gypsum

Fluosilicic acid product conversion from silicon tetrafluoride and hydrofluoric acid

Ethanol and methanol recovery

Complete Systems Supply

Bionomic recovery/production systems are offered as robust pre-engineered units with highest quality components to ensure long lasting performance with minimal downtime. Typical components can include a scrubber/recovery vessel, recirculation pumps, piping and valve networks, heat exchanger, instruments and controls, and everything else needed to satisfy the application needs. Depending on the service conditions, vessels are designed to standard atmospheric or ASME Code when high pressure or vacuum conditions will be encountered. Materials of construction can be specified by either end user, or Bionomic material engineers to meet the corrosive and structural demands of the application.

Full Documentation Package / Start-Up Assistance and Training

All systems are supplied with a full engineering documentation package to facilitate a smooth installation, start-up and servicing. The standard engineering submittal package includes:

Process, flow and instrumentation drawings complete with mass and heat balances and instrument set points

Equipment dimension drawings needed for sizing foundation supports, installation clearances and utility hookups

Complete bill of materials on components

Custom instructions for particular equipment operating conditions along with manufacturer’s component operating and maintenance instructions

Wind and seismic data per BOCA requirements and ASME code vessel calculations when applicable

Designed to reduce field labor costs, Bionomic recovery/production systems are offered in convenient, pre-packaged, skid-mounted, fully-piped assemblies for effortless installation and reduced start-up time.

Start-up assistance and operator training programs are available and can be custom tailored to satisfy your specific requirements.