BUTTERWORTH

Type MICRO100A Tank Cleaning Machine

The Butterworth Type MICRO100A automated tank cleaning machine provides 360° impact indexed coverage for the cleaning of the inside of tanks and process vessels.

Industries

The Butterworth Type MICRO100A is a highly versatile machine and is applicable in most all types of tanks for process, storage, and transportation. It can be used as a portable unit or permanently mounted.Operational

The Butterworth Type MICRO100A machine creates a pattern matrix similar to a ball of twine. A complete pattern is established when 36 axial revolutions of the body have been completed. During the process of this pattern build out, 4 cycles are established with each cycle increasing the density of the pattern matrix. The variable speed motor allows for flexible cycle times.

Specifications Summary

Pressure Range – Fluid: 0-1000 PSI (69 Bar)

Pressure Range – Air: 0-10 PSIG (0-0.68 Bar), Consumption, 1.4 – 3.1 SCFM (40-88 1/min.)

Maximum Temperature: Static : 300°F (148.89°C), Operational : 200°F (93.33°C)

Materials of Construction (As Standard): Wetted parts 316LSS, PTFE, other Parts (See manual for parts detail )

Lubrication: Flow-through (media lubricated)

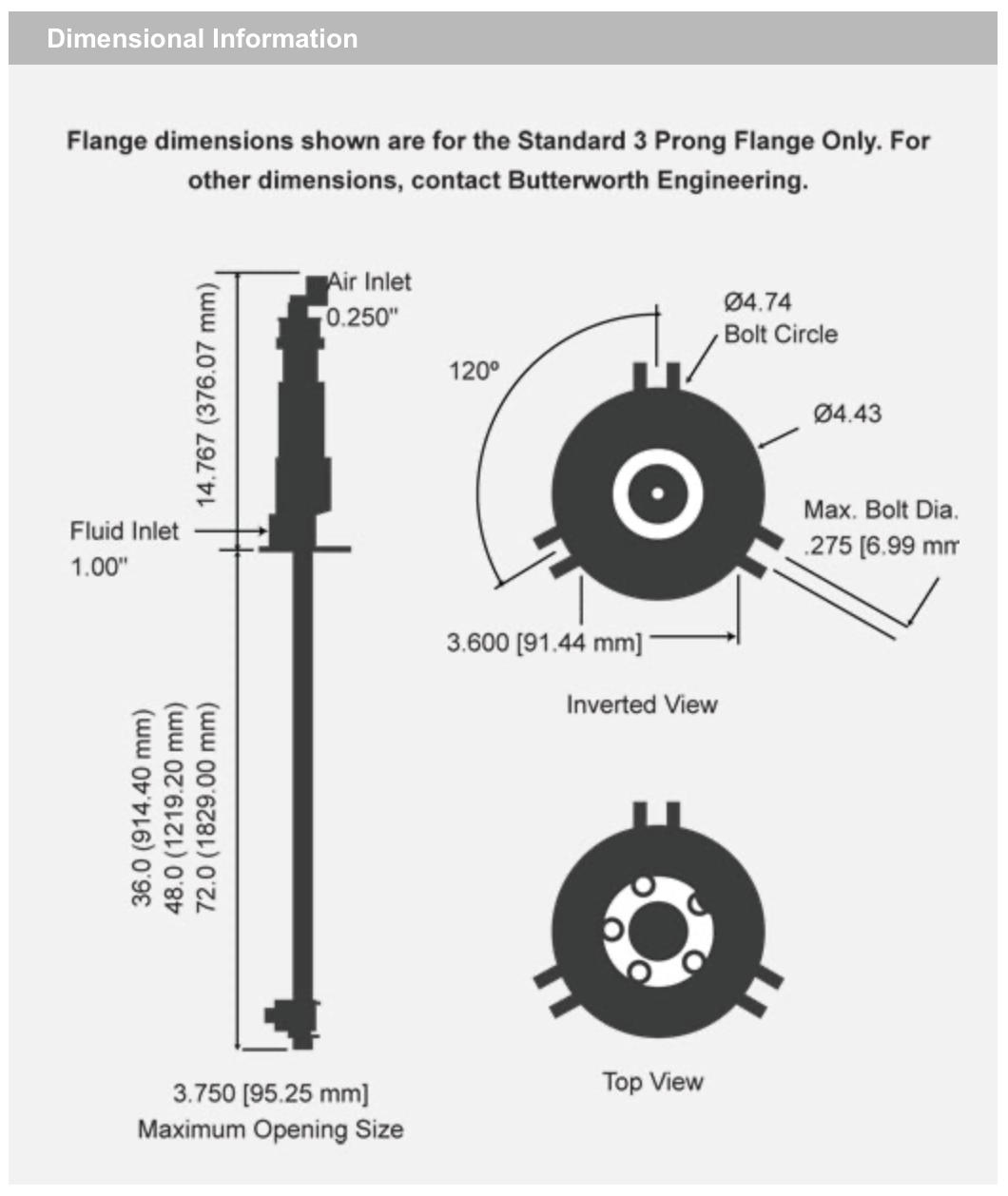

Minimum Opening: 3.75” (95.25mm)

Weights:

Tube Type 36

Flange Types 1&3: 14 lbs. (6.4 kg)

Flange Type 2: 24.50 lbs (11.1 kg).

Flange Type 2A: 29.50 lbs. (13.4 kg)

Flange Type 3A: 4.25 lbs. (6.5 kg)

Flange Type 3B: 17.00 lbs. (7.7 kg)

Tube Type 48

Flange Types 1&3: 15.5 lbs. (7.0 kg)

Flange Type 2: 26.00 lbs (11.8 kg).

Flange Type 2A: 31.00 lbs. (14.1 kg)

Flange Type 3A: 15.50 lbs. (7.0 kg)

Flange Type 3B: 18.50 lbs. (8.4 kg)

Tube Type 72

Flange Types 1&3: 18.5 lbs. (8.4 kg)

Flange Type 2: 29.00 lbs (13.2 kg).

Flange Type 2A: 34.00 lbs. (15.4 kg)

Flange Type 3A: 18.75 lbs. (8.5 kg)

Flange Type 3B: 21.50 lbs. (9.8 kg