FC LAB

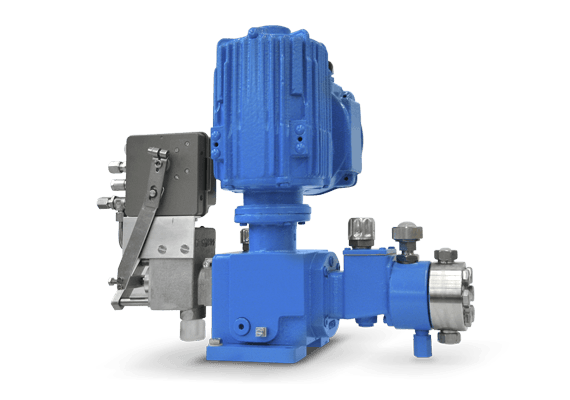

Micro-metering Lab pump

LEWA FC micro-metering pumps are used as laboratory pumps for metering very small quantities in laboratory environments. They meter with extreme precision and in a reproducible manner. Great value is placed on operational reliability and a broad spectrum of use in these environments. The metered flows have to be reproducible and controllable with high precision. The fluid has to be protected from any impurities.

Flow rates are 1.5 to 65 l/h per pump head. Using a plunger pump head, discharge pressures up to 160 bar are possible; with diaphragm pump heads, discharge pressures up to 400 bar. It is available in two different designs: as a diaphragm pump or a hydraulically and/or mechanically actuated packed plunger metering pump.

The LEWA FC micro-metering pump completely satisfies the requirements for a laboratory pump. It is highly efficient and meters at an accuracy of ± 1%. Multiple pump heads and drives can also be combined as desired to form multiplex pumps. This allows high flow rates or metering of multiple different fluids in a process sequence.

Highest metering accuracy

The flow rate can be configured with absolute precision. The micro-metering pump works with an accuracy of ± 1%. This allows you to meter fluids in a process in precisely defined quantities. LEWA pumps feature this enormous precision.

Control and monitoring electronics

We analyze the requirements that develop from your use and supply the suitable micro-metering pump including specifically adjusted control and monitoring electronics. This allows you to achieve maximum efficiency when operating your systems.

Accurately operating drive unit

Absolute precision is our standard: LEWA micro-metering pumps have accurately operating drive units with an electric drive and a plunger spring return that is friction-locking and absolutely free of play. Thus, they are particularly well suited for laboratory applications in which precise metering is required.

Leak-proof and odor tight

LEWA micro-metering pumps are not only leak-proof, but also absolutely odor-tight.

Oil lubrication

All moving parts are continuously lubricated with oil. The pump is protected from weather and splash water.

Integrated pressure relief valve

A pressure relief valve in the hydraulic part of the diaphragm pump prevents potential overload situations in operation. This valve is individually adjustable and can therefore be adapted to different operating situations.

Advantageous kinematics

The cam and spring drive has advantageous drive kinematics for the smallest metered flows.

Superior metal diaphragm technology

The metering pumps are equipped with sophisticated metal diaphragm technology, which enables discharge pressures up to 500 bar. At the same time, they still meter very precisely at an accuracy of ± 1%.

Wide adjustment range

The LEWA micro-metering pumps can be regulated in a wide adjustment range with consistently high efficiency and rigid compression curve.

Low-noise

The micro-metering pump is absolutely noiseless in operation, making it ideal for laboratory environments.

Dry-run safe and maintenance-friendly

The pumps are dry-run safe and maintenance friendly. No sliding seals or packages are inserted. This guarantees the highest process safety.

Ideal for supercritical and expensive fluids

FC micro-metering pumps are suitable for handling supercritical or expensive fluids due to precise and safe metering.

OPTIONS

Multiplex capability

Single drive units with vertically installed motor are space-saving. Alternatively, multiple drive units with identical or different output can be combined for pulsation reduction or recipe metering.

Minimization of pulsation

Multiple pumps designed for the minimization of pulsation can avoid the use of pulsation dampers. Ideal for perishable or slightly contaminated fluids (CIP/SIP capable).

Explosion-proof design

We supply pumps, equipment and systems on request in explosion-proof design for operation up to EX zone 1 . Thus, we guarantee maximum security.

Special micro filters

On demand, we equip your pump with special micro filters for dealing with high-purity fluids. This is especially recommended for applications in the pharmaceutical and food industry.

Special design materials

If the process demands it, wetted parts such as pumps heads and valves will be made of special materials such as stainless steel 316/316L (1.4401/1.4404), Hastelloy or Duplex steel and PVC.

Heating and cooling jackets

With heating and cooling jackets, our pumps are suitable for almost any temperature and can convey fluids at low temperatures or extreme heat.

Electrical stroke adjustment

Adjust the stroke length of your pump exactly to the specific metering task: LEWA pumps can be set fully automated by an electric stroke adjustment with integrated regulator.

Customized valves

LEWA uses numerous special types of valves such as specially hardened valves for liquified gases or valves with minimal dead space for the food and pharmaceutical production.

Complete control/regulation program

Our pumps and systems come with a complete control/regulation program. Moreover, the use of programmable logic controllers (PLC) is possible.